Understanding the Role of a Pressure Switch in Your Furnace: What You Need to Know

What Is A Furnace Pressure Switch?

A furnace pressure switch is a unique safety device specifically designed to monitor and regulate the air pressure inside the combustion chamber of a gas or oil furnace. The pressure switch ensures that the furnace operates safely by detecting any potential issues related to airflow or venting. If the pressure inside the combustion chamber is too high or too low, the pressure switch will shut down the furnace to prevent any hazardous situations.

The pressure switch comprises a diaphragm sensitive to changes in air pressure. It is connected to a tube that extends into the furnace's combustion chamber. As the air pressure inside the chamber changes, the diaphragm moves, either activating or deactivating the switch accordingly. This movement then sends a signal to the furnace's control board, which either allows the furnace to ignite and operate normally or stops the ignition process if there is a problem with the pressure.

A properly functioning pressure switch is essential for maintaining the safety and efficiency of your furnace. When working correctly, the pressure switch ensures sufficient airflow for combustion and that potentially harmful gases, such as carbon monoxide, are correctly vented outside your home. By understanding the role of a furnace pressure switch and recognizing potential issues, you can help ensure the safety and comfort of your living space during the colder months.

What Problems Can Occur With A Furnace Pressure Switch?

A furnace pressure switch is designed to ensure the safe operation of your heating system by monitoring the airflow and pressure within the combustion chamber. However, like any other component, it can experience issues that can affect your furnace's performance.

Below, we'll discuss some unique problems that can occur with a furnace pressure switch and how they may impact your heating system:

Stuck or Jammed Pressure Switch

Dirt, debris, or moisture can accumulate on the pressure switch's diaphragm, causing it to stick or jam. This can lead to the switch not activating or deactivating when it should, causing the furnace to malfunction.

Faulty Wiring or Electrical Connections

Loose or corroded electrical connections can disrupt the signal between the pressure switch and the furnace control board, leading to inaccurate pressure readings and potential safety hazards.

Incorrect Pressure Sensitivity

Over time, a pressure switch may lose its calibration and become too sensitive or not sensitive enough. This can result in the switch inaccurately detecting pressure changes, causing the furnace to shut down prematurely or fail to ignite.

Damaged Diaphragm

The diaphragm in the pressure switch is designed to respond to changes in pressure within the combustion chamber. However, it can become damaged due to wear and tear, rendering the switch ineffective in monitoring pressure fluctuations.

Blocked or Restricted Venting

A blocked or restricted venting system can cause pressure imbalances in the combustion chamber. This can lead to the pressure switch inaccurately detecting pressure changes and shutting down the furnace as a safety measure, even when there is no actual issue with the furnace itself.

Malfunctioning Inducer Motor

The inducer motor is responsible for drawing air into the combustion chamber and venting exhaust gases. If it malfunctions or fails, the pressure switch may detect insufficient airflow and shut down the furnace to prevent potential safety hazards.

Understanding the unique problems that can arise with your furnace's pressure switch is crucial in maintaining a safe and efficient heating system. Regularly inspecting and troubleshooting these issues can ensure your furnace's longevity and keep your home warm and cozy during the colder months.

Can You Troubleshoot A Furnace Pressure Switch?

While it's always recommended to consult a professional HVAC technician for any significant furnace-related issues, you can take a few troubleshooting steps to assess the condition of your furnace pressure switch.

This section will provide unique tips and tricks to help you diagnose and potentially resolve any pressure switch-related problems.

- Visual Inspection: A simple visual inspection is the first step in troubleshooting a furnace pressure switch. Check for any signs of damage, such as cracks, fraying, or loose connections. Also, ensure that the switch is securely mounted and that the tubing connected to it is free of blockages or kinks.

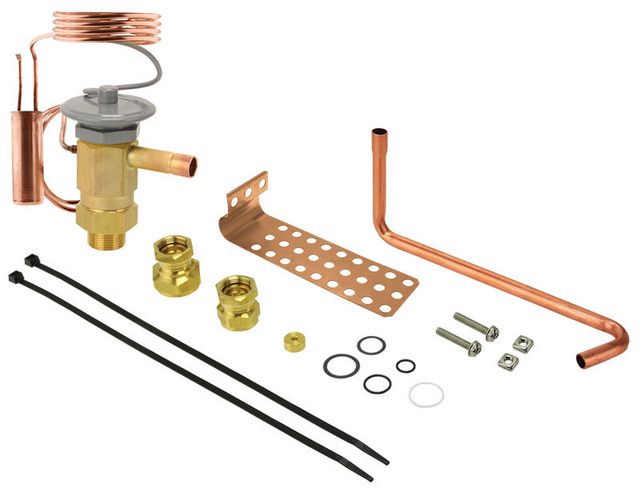

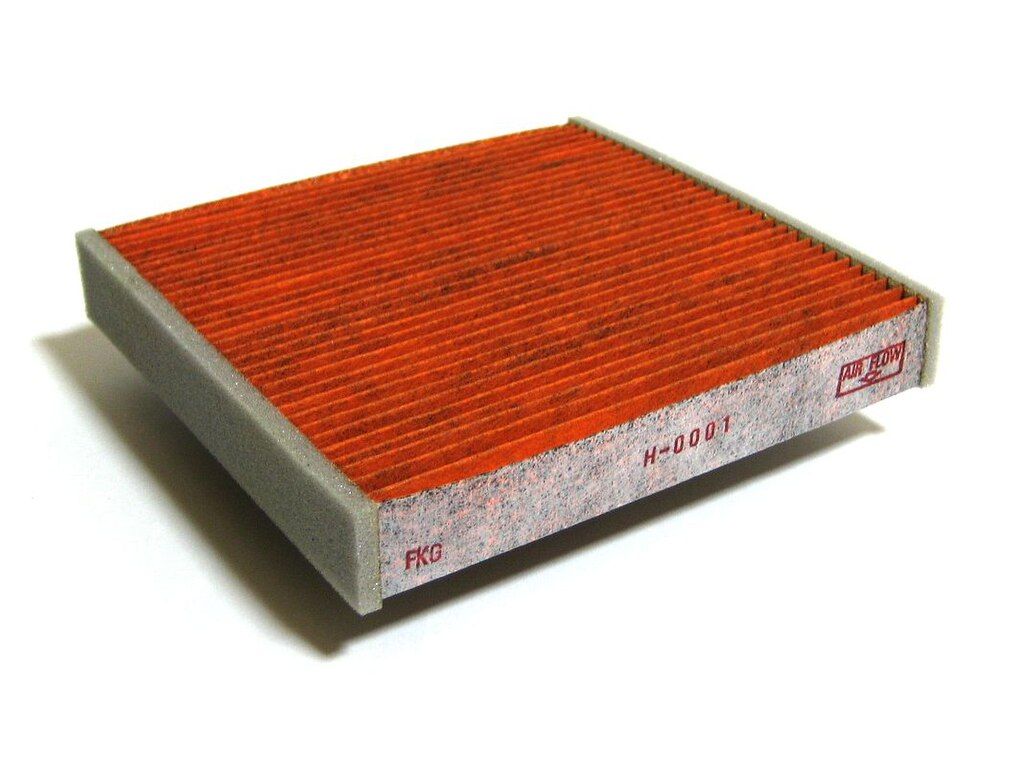

- Check the Furnace Filter: A dirty or clogged furnace filter can cause the pressure switch to malfunction, restricting the airflow needed for the switch to operate correctly. Per the manufacturer's guidelines, make sure to replace or clean your furnace filter regularly.

- Inspect the Draft Inducer Motor: The draft inducer motor is crucial in maintaining proper air pressure within the furnace. If this motor is faulty, it could cause the pressure switch to misread the pressure levels. Listen for any unusual noises from the motor or check for signs of wear and tear.

- Test the Pressure Switch: To test the functionality of your furnace pressure switch, use a multimeter. With the furnace off, disconnect the wires from the switch terminals and set the multimeter to measure resistance. Place the multimeter probes on the switch terminals, and if the reading is close to zero ohms, the switch is functional. If the reading is infinite or significantly deviates from zero, it's likely time to replace the pressure switch.

- Check the Venting System: A blocked or damaged venting system can cause the pressure switch to trip. Ensure that your venting system is free of obstructions, such as debris or bird nests, and that there are no visible signs of damage.

- Condensate Drain Line: A clogged drain line can trigger pressure switch issues. Regularly check and clean the drain line to ensure the proper functioning of your furnace.

Remember, while these troubleshooting steps can help identify pressure switch issues, it's

always best to consult with a professional HVAC technician for a thorough assessment and any necessary repairs. Keep your furnace running efficiently and safely by staying informed and proactive in maintaining its components, including the pressure switch.

Types Of Pressure Switches

This section will briefly discuss the various pressure switches you may encounter in your heating system. Understanding the differences between these switches can help you identify the one installed in your furnace and address any potential issues.

- Diaphragm Pressure Switches: Diaphragm pressure switches use an elastomeric diaphragm that flexes in response to changes in pressure. When the pressure reaches a specific setpoint, the diaphragm activates an electrical contact, opening or closing a circuit. These switches are often used in low-pressure applications and are known for their accuracy and reliability.

- Piston Pressure Switches: Piston switches utilize a piston mechanism instead of a diaphragm. When the pressure reaches the setpoint, the piston moves, activating an electrical contact. These switches are typically more robust and can handle higher pressure ranges than diaphragm switches. However, they may be less sensitive and accurate in certain applications.

- Electronic Pressure Switches: Electronic pressure switches utilize digital technology, employing pressure sensors and microprocessors to measure pressure changes. These switches can be more versatile, with adjustable setpoints and various output options. They also offer improved accuracy and are less susceptible to mechanical wear and tear.

- Vacuum Pressure Switches: Vacuum pressure switches function similarly to other pressure switches but is designed specifically for low-pressure and vacuum applications. They monitor negative pressure levels and trigger an electrical contact when a specific vacuum level is reached.

Depending on the specific requirements and operating conditions, these pressure switches can be found in various furnace systems. Understanding the type of pressure switch in your furnace can help you diagnose problems and ensure optimal performance.

Recognizing Signs of a Failing Pressure Switch in Your Furnace

A furnace pressure switch plays a vital role in ensuring your heating system's safe and efficient operation. It monitors the air pressure in the combustion chamber, ensuring the furnace ignites only when the pressure conditions are optimal. A malfunctioning pressure switch can lead to potential safety hazards or reduce your furnace's performance. This article will discuss the signs of a failing pressure switch and how to address them to maintain a warm, comfortable, and safe home.

Furnace Fails to Ignite

One of the most common signs of a failing pressure switch is when the furnace fails to ignite. If the pressure switch is malfunctioning, it may not allow the furnace to ignite, even if the pressure in the combustion chamber is within the acceptable range. This can leave you with a cold home and require professional assistance to diagnose and fix the issue.

Frequent Cycling On and Off

If you notice that your furnace is frequently cycling on and off, it could be a sign that the pressure switch is not working correctly. A malfunctioning switch may inaccurately detect pressure fluctuations, causing the furnace to shut off prematurely or fail to ignite when needed. This can lead to an uncomfortable temperature in your home and increased energy consumption.

Inconsistent Heat Output

A failing pressure switch can cause inconsistent heat output from your furnace. If the switch is not correctly detecting the pressure within the combustion chamber, the furnace may not burn fuel as efficiently, resulting in uneven or insufficient heating throughout your home.

Unusual Noises

A damaged pressure switch can sometimes produce unusual noises, such as clicking or humming. These noises may be more noticeable when the furnace tries to ignite or cycle on and off. If you hear any strange sounds coming from your furnace, it's essential to have it inspected by a professional HVAC technician.

Furnace Shuts Down Unexpectedly

If your furnace shuts down unexpectedly or frequently goes into a safety lockout mode, it could be due to a malfunctioning pressure switch. The switch may inaccurately detect a pressure issue, causing the furnace to shut down as a safety precaution.

Recognizing the signs of a failing pressure switch in your furnace is crucial to maintaining a safe and comfortable home environment. By staying vigilant and addressing potential issues promptly, you can extend the lifespan of your furnace and avoid potential safety hazards. Remember, it's always best to consult a professional HVAC technician for a thorough assessment and necessary repairs to keep your heating system functioning optimally.

Understanding the role of a pressure switch in your furnace is essential for maintaining a safe and efficient heating system. As a vital safety component, the pressure switch ensures proper air pressure and ventilation, safeguarding against hazardous situations. Familiarizing yourself with its function, common issues, and troubleshooting methods can help you identify and address problems before they escalate. Additionally, recognizing the various types of pressure switches and knowing how to test them can aid in diagnosing issues and maintaining optimal furnace performance.

By staying informed and proactive in maintaining your furnace's components, including the pressure switch, you can ensure the safety and comfort of your home throughout the colder months. Although some troubleshooting can be done independently, always consult a professional HVAC technician for a thorough assessment and any necessary repairs. Keep your furnace running efficiently and safely, providing you and your family with warm, cozy living space all winter.

If you encounter any problems with your furnace's pressure switch or other HVAC system components,

contact All-Star HVAC in Knoxville. Our experienced technicians can diagnose and resolve issues to ensure your home stays comfortable and safe year-round.

Payment Options